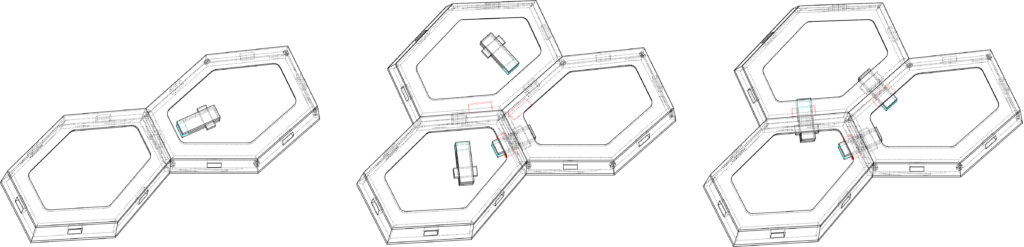

16.8.2019, Sydney: Wedge-joints are ideal connectors for wood and have been used in traditional handcrafted woodworking for centuries. The diagonal shape of the wedge allows not only to compensate for tolerances, which are natural to wood and wood products, but the wedge joint also allows for a gradual tightening of the joint. The “HexBox Canopy”, a collaborative research project between the DTC and the Code-To-Production Team, presents a new type of wedge joint for the assembly of prefabricated plywood box components.

Video on LinkedIn

Article: Architecture AU / Robotically fabricated canopy, 25.10.2019

Article: CarterHoltHarvey Plywood, 03.2020

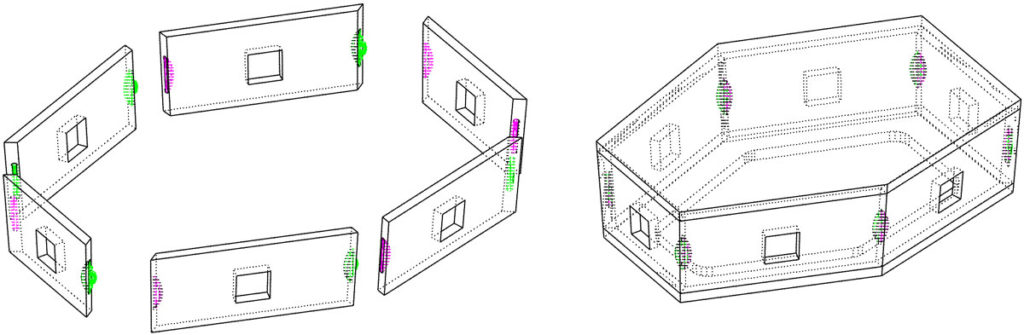

Consisting of prefabricated hexagon-shaped boxes made from laminated veneer lumber (LVL) plates, the structure was realised as a collaboration between researchers and students from the University of Kaiserslautern and the University of Sydney. After some preliminary planning and robotic cutting of the plate elements, the canopy was completely assembled by all of the students during a one week workshop.

When working with a large amount of differently shaped elements, manual drawing or cutting is out of the question, instead the project is taking advantage of automated processes. When it comes to the assembly, this can be simplified through integrated joints, where the position and alignment of the parts results from their geometry. In the Hexbox project, the plates within a module where glued with a 1K PUR adhesive, which provides a high-performance joining solution for thin plates, however it is limited to a prefabrication environment and requires guides for the positioning and clamping of the parts to be glued. While this is relatively simple for orthogonal boxes, gluing is challenging for our free-form boxes, where the side plates are at rotated at various different angles. We solved this challenge by using Lamello Tenso connectors , which were used as positioning and gluing aides. For the top and bottom plate, they were not required, since these two planes are parallel and pressure for the gluing can easily be applied with standard devices.

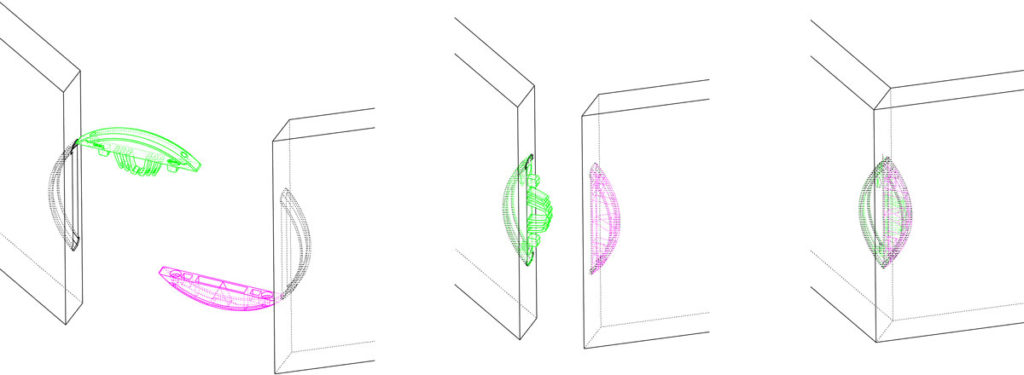

For a rapid and precise on-site assembly, the HexBox project uses novel wedge connectors, inspired by traditional wedge joints which were a common method in hand crafted carpentry and cabinetmaking. Due to their angular wedges, such joints allow to compensate for certain tolerances that are intrinsic to the naturally grown material wood. These novel joints can be produced from waste material such as the smaller offcuts from the box component fabrication.

Rather than attempting ultra-precisely fabricated elements, the wedges allow to assemble boxes even when there are small imprecisions. Additionally, these joints allow for pulling and forcing the boxes together, closing gaps between the elements which may occur during assembly, similar to metal screw connectors. The closing of such gaps is critical for the overall precision and performance of the structure.

The HexBox Canopy project has been generously supported by our sponsors Lamello SA, PMI Engineers (Thomas Williams) and Carter Holt Harvey Plywood. The travel of the Kaiserslautern team was kindly supported by the German DAAD PROMOS funding.

HexBox Project Team: Code to Production Sydney (Eduardo Oliveira Barata) + DTC Kaiserslautern (Jun. Prof. Dr. Christopher Robeller): Muneeb Ahmed, Carla Alkhouri, Nazgol Asadi, Minh Au, Philip Becker, Benedikt Blumenröder, Michael Calarco, Michael Connolly, Guobin Dai, Dominik Diehl, Joseph Emmi, Ziyun Gao, Satoshi Hoshino, Alvin Hui, Geun Mo Kim, Florian Lapport, Jian Howe Lee, Jingwei Li, Sarah Lutgen, Albert Marhoffer, Lynn Masuda, Jan Neklapil, Khoa Nguyen, Chaoran Ni, Liezl Pajarin, Manuel Scheib, Felix Schmidt-Kleespies, Wenxi Shi, Anna Specchio, William Stephenson, Haochen Sun, Ernest Sun, Valentino Tagliaboschi, Prudence Tang, Christian Tsitsos, Victoria Vuong, Rodney Watt, Iridia Xanthou

We would like to thank our sponsors and supporters: Lamello SA, PMI Engineers (Thomas Williams), Carter Holt Harvey Plywood, DAAD, KUKA AG, IMES-icore GmbH, Doris Simon, Nina Huber, Yang Liu, Johannes Braumann and Magnus Volkmann.